Timing Belt - Tensioning

Proper tensioning cannot be stressed enough: too loose of tensioning will cause the timing belt to ratchet (tooth jumping), while too tight of tensioning will possibly cause damage to the bearings, shafts and other drive components besides dramatically reducing timing belt life. The correct timing belt tension is the lowest tension at which timing belts will transmit the required mechanical power and not ratchet teeth when the drive is under a full load.

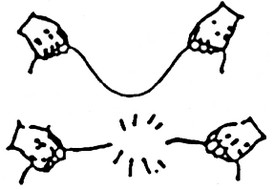

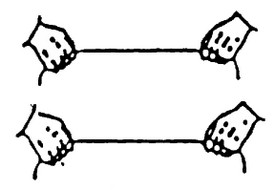

Loose timing belt tensioning acts like a loosely-held piece of string, with a snapping action as in a high torque situation the string or timing belt will break because the added stress is more than the timing belt was designed to take. While a taut string or timing belt can stand a strong pull.

Take up any loose slack in the timing belt by adjusting the center to center distance between the two timing belt pulleys. Before any final tensioning is to be applied make sure that the timing belt teeth are fully seated in the tooth grooves on both timing belt pulleys. Check to make sure that the timing belt teeth stay seated in the tooth grooves by rotating the drive system by hand. After the pre-tensioning steps are completed there are several methods for verifying proper final tensioning.

Numerical Method (Force/Deflection)

By measuring the deflection of the timing belt with a known force the required tension can be applied. Specifically the target tension is broken into two values deflection force and distance. Using these two values along with a straight edge and a pencil style tension gauge you can install a timing belt properly. While being a relatively quick method, this method is usually not very accurate. Primarily due to the difficulty in measuring small deflections and forces common in small timing belt drives. This method is better suited for larger drives with long timing belt spans.

F = Deflection Force

F = Deflection Force

q = Deflection, 1/64" per inch of span length

c = Center Distance

D = Large Pulley Pitch Diameter

d = Small Pulley Pitch Diameter

P = Span Length

Before beginning, inspect the timing belt for damage and verify that the timing belt pulleys are properly aligned (parallel and angular).

- Shorten the center distance or release the tensioning idler to install the timing belt. Do not pry the timing belt onto the timing belt pulleys.

- Place the timing belt on each timing belt pulley and ensure proper engagement between the timing belt pulley and timing belt teeth.

- Lengthen the center distance or adjust the tensioning idler to remove any timing belt slack.

- Using a tape measure, measure the span length of the drive in inches. Refer to dimension “P” in the diagram above. The span length “P” can be calculated using the center to center distance calculators available within our technical section on our website or through any of the timing belt manufacturer’s websites.

- First determine the proper deflection force required to tension the timing belt. Deflection forces are given in the timing belt manufacturer’s tables and/or power transmission drive design online calculators. Then place a straightedge across the top of the timing belt. At the center of the span length “P” apply force using a pencil style tension gauge perpendicular to the span length “P” (see below picture).

- When using a pencil style tension gauge, the deflection scale is calibrated in inches of span length. Set the (large) O-ring on the body of the pencil style tension gauge at the dimension equal to 1/64” inch for every inch of span length.

Example:

If the span length “P” is 16” inches, the deflection would be ¼” inch (1/64” multiplied by 16” equals ¼” inches)Next set the (small) O-ring on the plunger at zero (0) this measures the deflection force in (lbs).

-

The below illustration demonstrates how to use the pencil style tension gauge. Place the gauge perpendicular to the span length “P” with the rubber plunger against the palm of your hand. Deflect the timing belt until the bottom of the (large) O-ring is even with the bottom of the straight edge. Release the pressure on the gauge and read the measurement indicated by the (small) O-ring in pounds of force required to deflect the timing belt.

If the measured force is less than the required deflection force, lengthen the center distance.

If the measured force is greater than the required deflection force, shorten the center distance.

- When using a pencil style tension gauge, the deflection scale is calibrated in inches of span length. Set the (large) O-ring on the body of the pencil style tension gauge at the dimension equal to 1/64” inch for every inch of span length.

- After the timing belt is properly tensioned, lock down the center distance adjustments and recheck the sprocket alignment. Recheck the timing belt tension and alignment after eight hours of operation to ensure the drive has not shifted.

Sonic Tension Meter

The sonic tension meter provides the most accurate tension measuring available.

The sonic tension meter provides the most accurate tension measuring available.

Timing belts, like string, vibrate at a particular natural frequency based on mass and span length.

By measuring this natural frequency of a free stationary timing belt span the sonic tension meter is able to instantly compute the static timing belt tension based upon the timing belt span length, timing belt width and timing belt type.

The sonic tension meter provides accurate and repeatable tension measurements while using a nonintrusive procedure, the measurement process itself doesn't change the belt span tension.

Measurement is made by strumming the timing belt like a guitar string to make it vibrate and then hold the meter close to the resonating timing belt to take a measurement.

ContiTech - Mechanical Power Transmission Drive Design Calculator

Both of the tensioning methods above require calculations to arrive at the proper tension value. Since time is of the essence in any project, I will not consume your time with details on how to manually calculate the required tensioning values. A tool that I find extremely valuable in both mechanical power transmission design and also in calculating timing belt tensions is ContiTech - Mechanical Power Transmission Drive Design Calculator. This computer based program is an extremely valuable tool to add to your collection, and the best thing about it is that it's free. This program can be found on the Continental ContiTech website and/or through a link on the Pfeifer Industries website under the Technical section.

Both of the tensioning methods above require calculations to arrive at the proper tension value. Since time is of the essence in any project, I will not consume your time with details on how to manually calculate the required tensioning values. A tool that I find extremely valuable in both mechanical power transmission design and also in calculating timing belt tensions is ContiTech - Mechanical Power Transmission Drive Design Calculator. This computer based program is an extremely valuable tool to add to your collection, and the best thing about it is that it's free. This program can be found on the Continental ContiTech website and/or through a link on the Pfeifer Industries website under the Technical section.

Not to be out done by its competitors the other timing belt manufacturers also offer a similar program for calculating the proper tension value.